Precision Engineering You Can Trust

Production Turned Parts has been producing high quality CNC machined parts for over 30 years. Capabilities include CNC turning and milling, product development, general engineering and assembly.

Production Turned Parts (PTP) is a 100% New Zealand–owned and operated engineering company based in Drury, Auckland. Founded by Ron and Pauline Gill and proudly owned by Ben Schultz since 2011, we have been delivering precision components and engineering solutions for over 30 years.

We support industries including aerospace, automotive, electrical, marine, fluids, gas, instrumentation, manufacturing, construction and agriculture manufacturing components with exceptional accuracy and tight tolerances. Our experienced team combines industry expertise with advanced CNC technology to produce both short-run and high-volume parts efficiently.

At PTP, we take pride in our strong reputation for quality, reliability, and customer-focused service across every project we undertake.

About

Services

Capabilities

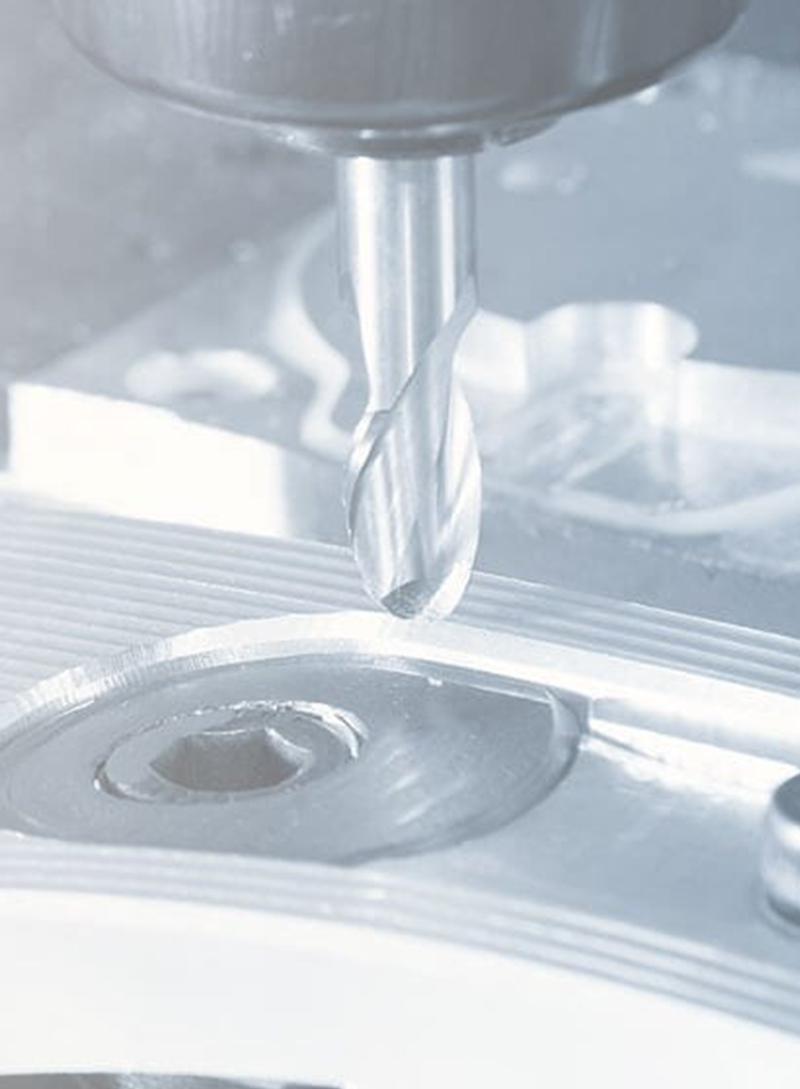

Precision machining

Production CNC Machining

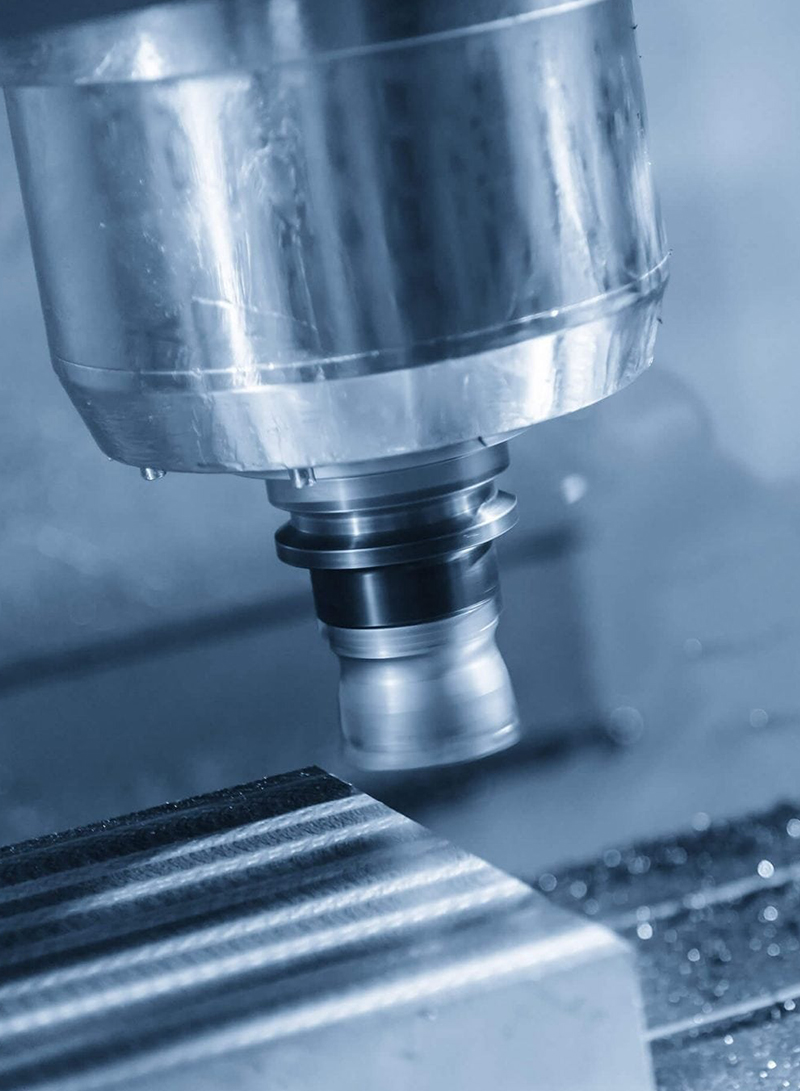

3 and 4 Axis Milling

CNC Lathes, Bar Fed and Chucking with Live Tooling and Y-Axis

Assembly

Engraving of components

MIG Welding

General Engineering

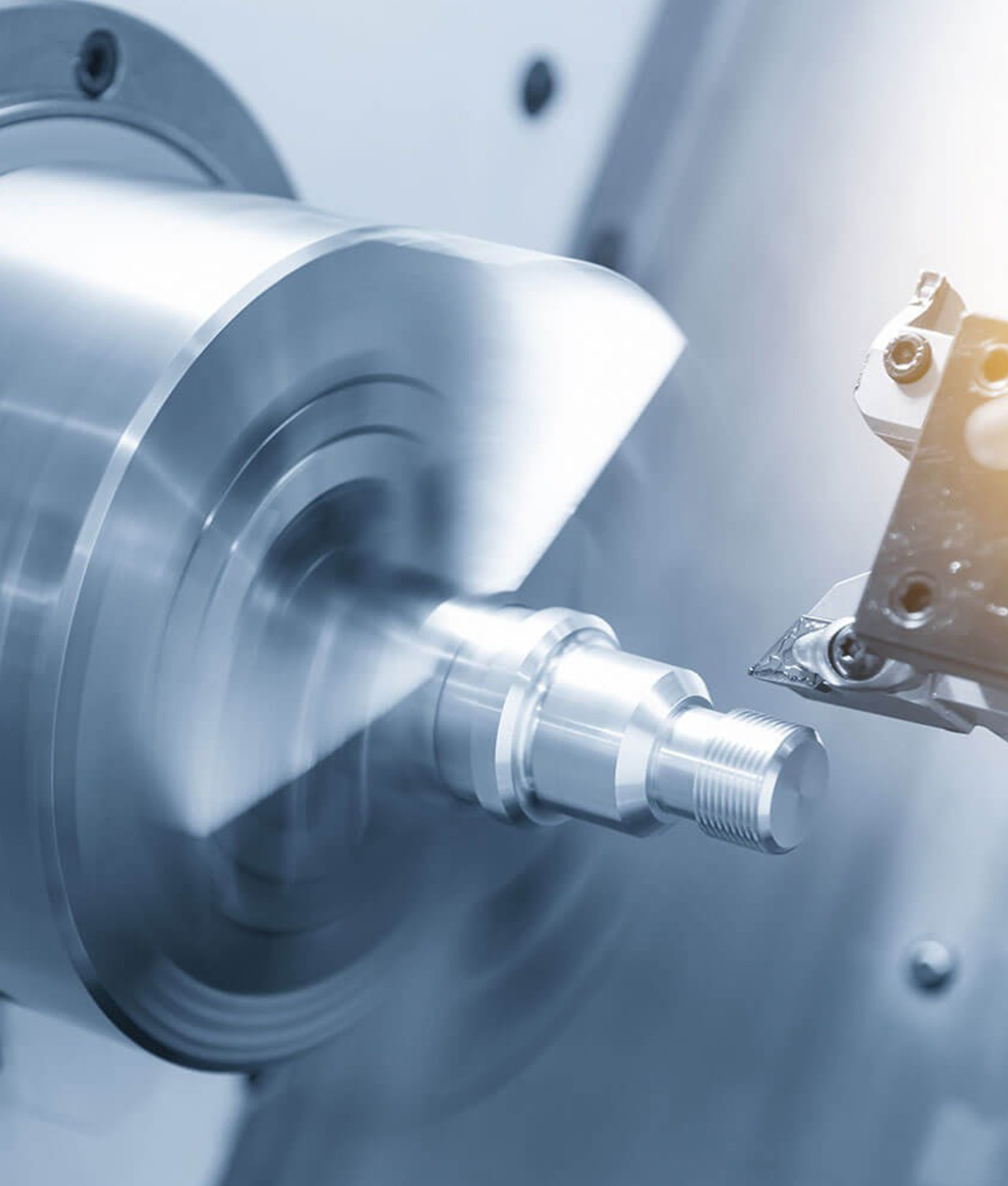

CNC Machining

We operate a range of CNC Lathes including single, twin spindle, Y-axis and live tooling. Our Mills have 3 and 4 Axis capabilities. We can complete components in one operation that are cross drilled, have tapped holes and milled faces. This increases accuracy, quality and reduces the cost of the finished parts.

Product Development

We have inhouse design capability available and provide sample runs of developmental products. We manufacture to customer drawings or support the development process with design and manufacturing solutions. We have established relationships with local and international subcontractors for additional treatments including anodising, heat treatment and plating.

Materials

We machine a variety of ferrous and non-ferrous materials including Aluminium, Brass, Copper, Bronze, Titanium, Stainless Steel, Speciality Steels including Tool Steels, and Plastics. We support local suppliers but also have established relationships with offshore contacts for specialised metals, components and plastics.

Compliance & Quality Control

We maintain end to end traceability of materials and production processes within our supply chain. This ensures consistency, transparency and traceability of our precision manufactured components. Where required, we can supply Compliance Documents and Material Test Certificates. Our purpose-built, temperature-controlled QC Room is equipped with an extensive range of measuring equipment to ensure our parts meet specification.

Our machines produce high quality finishes and precision tolerances on short and long run production machining.

Compliance

We have a number of customers who require high level compliance for their parts. We trace all of our material purchases and product movement within the plant. We have a purpose built temperature controlled QC Room and an extensive range of measuring devices from Vernier and Micrometers to gauges.

Suppliers and Subcontractors

Production Turned Parts has strong relationships with suppliers and subcontractors. We prefer to purchase locally and have relationships with off shore suppliers for specialised items.

Ready to Grow?

Get in Touch

Message from website sumit form

Production Turned Parts

4/65 Firth Street, Drury

Auckland, New Zealand

09 294 8102

ptp@proturn.co.nz